Isovation manufactures and assembles its products with the most suitable materials to combine thermal performance, mechanical resistance, flat delivery and respect for the environment.

Our Research & Development department strives to find new materials and new processing and manufacturing techniques and using innovative materials.

Materials can be innovative through their technicality, their performance, but also the respect for the environment.

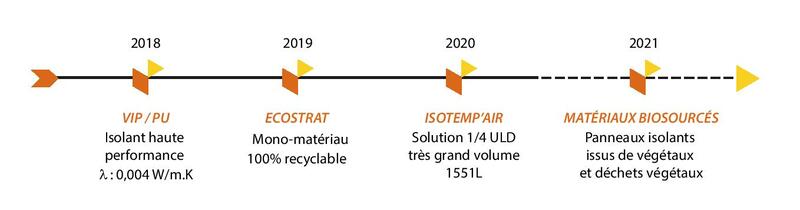

Our developments in recent years:

Nos développements ces dernières années :

ISOSTRAT

PET/XPS/PET Complex

Thickness : 3mm, 4mm or 5mm

Coefficient of thermal conductivity* :

λ = 0.031 W/m.K

ECOSTRAT

PS mono-material complex

Thickness : 3mm, 4mm or 5mm

Coefficient of thermal conductivity* :

λ = 0.027 W/m.K

XPS

Extruded and expanded PS

Thickness : 20mm, 30mm, 40 mm or 60mm

Coefficient of thermal conductivity* :

λ = 0.034 W/m.K

VIP

Vacuum insulation panels

Standard thickness : 30mm and other thickness available

Coefficient of thermal conductivity* :

λ = 0.004 W/m.K

100% recycled foam

Heat reflection

Aesthetic

Foldable (flat packed delivery)

Mono-material : 100% recyclable

Hydrophobic

Foldable (flat packed delivery)

100% recyclable

Better performance than EPS (expanded polystyrene)

Ecologically better than PU (polyurethane)

Not friable

Panels (flat placked delivery)

Very high thermal performance : 30mm VIP = 210mm XPS

Mechanical resistance due to the exterior layer of 5mm PU

Not friable

Panels (flat placked delivery)

*Plus le coefficient de conductivité est faible, plus la performance de l’isolant est élevée